The Alberta Recycling Management Authority is in the midst of a new event that challenges students at the University of Alberta to find better ways to deal with used plastic oil containers.

Last year, Albertans purchased 90.3 million litres of oil within 2.31 million kilograms of containers, as well as 4.48 million kilograms of oil filters. While processes exist to recycle the waste this demand creates, the sheer volume calls for even more solutions, the authority said.

"Used oil containers have challenges," Michael Robertson, the authority's program manager, told Taproot. "Innovations that improve the efficiency or expand the end markets could help create more stable demand that would help support a sustainable program that, ultimately, attracts and retains businesses."

The Student Innovation Challenge: Used Oil Plastics, which kicked off on Jan. 17 and runs until March, calls for engineering students at the graduate and undergraduate levels to team up and conceptualize improvements to any part of the life cycle of the containers that hold motor oils or other lubricants.

"This is theoretical, most likely, for a lot of this work," Robertson said. "To the best of (the students') ability, they're trying to estimate what these (innovations) might be for the real-world application."

The authority decided to work with the university because of the school's knowledge in working with resins like plastic, Robertson said.

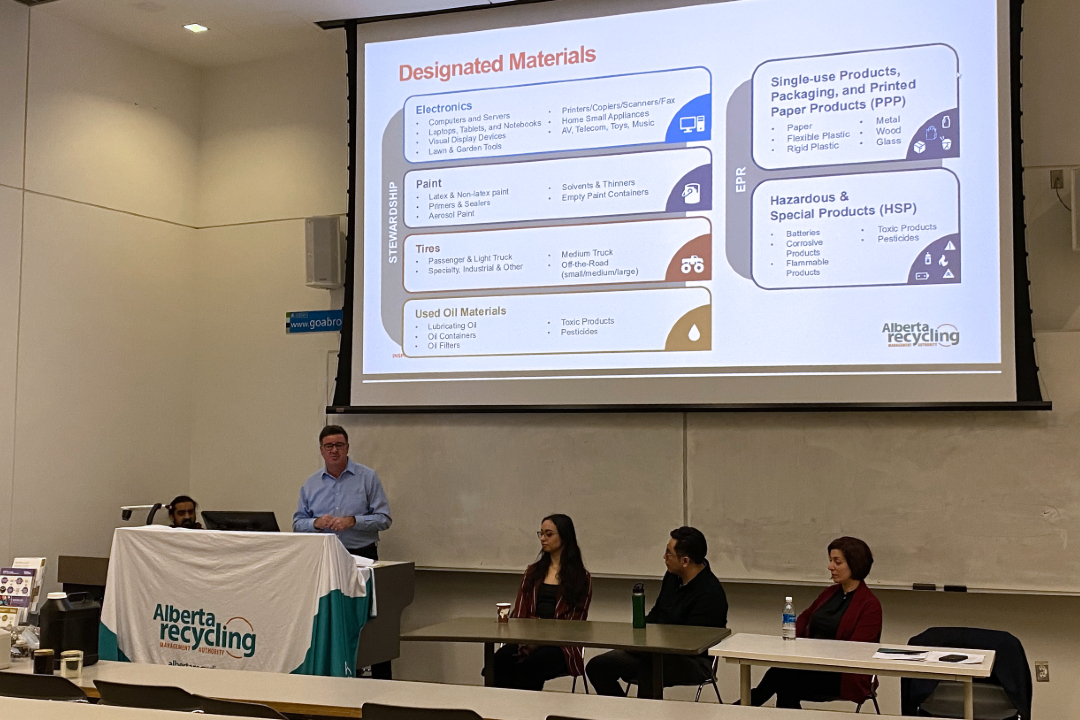

The Government of Alberta created the recycling authority in 1992 to oversee recycling for materials that don't go to bottle depots or municipal recycling facilities. The organization's responsibilities include used tires, electronics, paints, and oils, including oil containers. In the 2023 to 2024 reporting period, the authority recovered about 96% of plastic oil containers sold in Alberta at depots and partner organizations. These plastics are usually turned into either pellets or scraps for new products, like plastic jugs that hold oil, but also can be used in composite products like fence posts.

The authority works with 14 different businesses to process used plastics that contained oil, including Aevitas in Edmonton and RPM eco in Spruce Grove. Robertson said these plastics are "less desirable" for businesses that recycle plastics because oil needs to be cleaned from them for certain processes, and because they have narrower applications than other used plastics.

Finding more ways to repurpose these materials is good for business, he said. Roughly 40 students across eight teams in the challenge are already working to do just that. One nascent idea is to use 3D printing somewhere in the life cycle of these plastics.

"The students have an incredible range of solutions that they've been talking about," Kieran Ramnarine, the experiential learning coordinator in the university's faculty of engineering, told Taproot. "We wanted to leave the board open for them to come up with whatever it could be. Maybe at the market disruption (stage) from the start of the value chain, maybe it's something about a process somewhere along the way, maybe it's an end product or a later-in-life product."

The University of Alberta's Kieran Ramnarine (left) is coordinating a challenge for students from the Alberta Recycling Management Authority (CEO Ed Gugenheimer stands next to Ramnarine) to find new ways to recycle, reuse, or improve plastics that contained oil. The team that places first will win $3,000. (Supplied)

Beyond solutions for used plastics that contained oil, the challenge is a way for students to learn management skills within teams, and to advance their thinking on circularity.

Circularity is the idea that one should think of a product through its entire life cycle, including after it is used, Ramnarine said. "Thinking about process, thinking about the design, and thinking about the whole cycle of the material, I think was an important part of the competition."

Outside of the competition, on April 1, the recycling authority will permanently expand its electronics recycling program after piloting the idea since 2020. Once this happens, power tools, microwaves, musical instruments, and more products will be recyclable through the authority. Further expansion of the used electronics program includes materials used in renewable energy such as solar panels, electric vehicle batteries, and wind turbine components. The authority's website says Alberta will be the first province in Canada to offer recycling for the components of renewable energy products.

"One of the offshoots that we've been working on is identifying and validating (solar) panels that are still good enough to be reused," Robertson said. "What does that look like, and how we can bring those back into the market to be used again?"

Elsewhere in Alberta recycling, the Alberta Beverage Container Recycling Corporation is working with NAIT's Applied Research division to improve recycling outcomes for beverage pouches, like the ones that hold Capri Sun.

Back to the U of A innovation challenge for plastics that contained oils, in March, representatives from the authority and the university will judge the student teams on their solution's innovation, market value and proposition, timelines, and budget. Winning teams will receive prizes of $3,000, $2,000, and $1,000 for first, second, and third place, respectively.

Correction: This story has been corrected to include the correct date that the Alberta Recycling Management Authority was created.